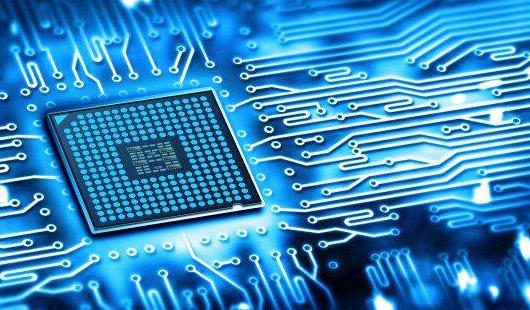

Semiconductor testing is an essential in today’s digitally advanced world to guarantee compliance with industry quality requirements and specifications. Semiconductor Test System is required to guarantee fault-free semiconductor devices because manufacturing defects are unavoidable. The fundamentals of semiconductor testing, tools, operational ideas, and industry trends are covered in this article.

Testing of Semiconductor IC

Integrate circuit (IC) validation is routinely carried out during standardized chip creation to examine the chips when they are produced. Wafer penetration is the first step in IC testing before actually etched wafers are divided and transformed into pre-packed chips. The test findings are the sole way to find and isolate many problems in modern processes. The gates that regulate time to yield, time to market, and time to quality are tests.

The three main categories into which testers fall are boolean, memory, and analog testers. These tests involve wafer examination and container testing. A probe and a sensitivity chip are used to test wafers, and a controller, a checking socket, and a checker are used to inspect packages.

Different IC Tests

Functional tests, architectural tests, and parametric tests are the three main categories of integrated semiconductor test systems.

The chip is placed through all the various operational tasks intended to carry out during a functional test. An activity that highlights any faults that might be discovered due to production mistakes is performed on the product as part of a structural test. Specific parameters, such as current and voltage values, will be identified through a parametric test. Parametric testing is used to identify a device’s specific electronic properties.

Automated Test Equipment Overview (ATE)

A tool called automated test equipment (ATE) is designed to execute a single test or a series of tests on one or more devices simultaneously. One of the many applications for ATE testers is the testing of electronics, equipment, and semiconductors.

A box housing extremely sophisticated electronic metering and stimulation devices controlled by a PC or workstation can represent an ATE system. This processor controls the information that is sent to the machinery to produce stimulus signals and configure them. It also compiles and analyzes data that has already been recorded and analyzed by the ATE system’s hardware.

How Do the Different ATE Components Function?

An automated test system must consist of the following five components: hardware, programming, test automation, signal generators, and checking probes or handlers.

The piece of software that controls the data stream of stimuli and stats is known as a “Testing Regime” or “Application Program” in the ATE sector. A different test program must be written for each type of automation testing instrument and each microprocessor to be assessed.

An ATE network also includes a “Device Under Test” electronic interface, which facilitates communication with the object being tested. The DUT and ATE are independently connected in large-scale manufacturing using a positioning tool. The handler is a positioning device for integrated devices. Semiconductor wafers are handled using a “probe”.

The Benefits of ATE

ATE systems shorten testing timelines and produce considerable financial benefits for enterprises by modernizing and improving testing tools, processes, and procedures that were previously manual. Automation ensures test and cycle times consistency by eliminating highly inconsistent operator intervention. As much as technology is evolving, testing tools are also being advanced to save time and offer convenience.

What Makes Transistor Self-Heating a Serious Issue?

According to a paper presented at the IEEE 39th VLSI Testing Symposium in 2021, transistor identity is a significant issue that is the subject of substantial investigation (VTS). Self-heating significantly impacts on-chip performance, which also affects threshold voltage, reliability, output permeability, and component dispersion.

In conclusion, a semiconductor Test System is a way to safeguard the electronic devices being launched in the market. Besides, they must adhere to government policies when introducing a product for public use.

Leave a Reply